Retort - Autoclavable Pouches

What is a Retort Pouch?

A retort pouch is a sterilizable flexible pouch constructed of a thin, bonded film that can withstand processing a product inside at 250°F (120°C) for a minimum of 50 – 55 minutes. It is probably most familiar to the public for tuna fish in a pouch, one of the industry’s earlier adopters. IMPAK has retort pouch customers with standing orders of sufficient volume that we maintain inventory on these products on a regular basis. This includes flat pouches, stand up pouches, drum liners, and spout pouches.

Custom Pouches: Many pouches are produced to customer specifications with a choice of sizes, styles, and colors (including clear materials), printed and unprinted. For more information, provide the size, application, and quantity required to: requests@sorbentsystems.com

Why is the Retort Pouch Revolutionary?

Many consumers may not be aware that some foods are uncooked when packaged and then cooked right in the sealed pouch. This revolutionary packaging process is called retorting and is the same process as autoclaving, which is the ability to heat and sterilize the packaging and contents. These methods are used in the food and non-food manufacturing industry to commercially sterilize instruments and components, or to cook product after it has been placed into its package. The retort pouch is filled with the product to be heated, is then hermetically sealed (airtight), and processed according to industry guidelines for time and temperature. Usually, this is a minimum of 50 minutes at 250°F. Retort bags are constructed from laminated plastics and thin metal foils, taking the place of traditional cylindrical metal cans or glass jars, and the flexible retort pouches are then processed in a heated pressure vessel.

Commercial vs Home Retorting

There are many regulations spelled out by the U.S. Department of Agriculture and the Food and Drug Administration pertaining to safe retort packaging practices for commercial food producers. Much of this guidance is about choosing the proper materials (pouches) and to correct usage of commercial-grade retort equipment, including maintaining a precise 1 atmosphere pressure environment in the retort. IMPAK is confident in the quality of our retort rated pouches for use in these applications. When employing the proper methods for commercial retort packaging, our pouches help to make shelf-stable food products that can be enjoyed years after they are first pouched and poached.

There are many people who practice “canning” with flexible retort pouches at home, often including a chamber vacuum sealer and a pressure cooker in the process to replicate the commercial retort environment. While e are aware that people have been sharing instructions on how they have been using retort pouches at home for years, there are several reasons why IMPAK Corporation CANNOT recommend this practice. Given that the retort process frequently involves raw oods that are cooked inside the pouch, the likelihood that our pouches will burst if not properly pressurized in a commercial-grade retort, and the fact that home users are not bound to abide by the regulations for commercial producers, the risk of food safety issues is too great. The canning technique this is based around for home preservation was originally backed up with a government study to find the most reliable methods for canning - using cans and mason jars specifically. No such wide ranging study has been made for this process using a retort ready pouch.

Retort Pouch Production

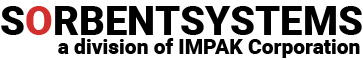

The key to retort pouch production is high-quality lamination. The layers of plastic and thin foils create a barrier impervious to gases and moisture entering or exiting the packaging. IMPAK understands the technology and methodology required to bond the layers of a retort pouch together with a secure seal and a polished look. Our machines can produce retortable and autoclavable flexible packaging from small sizes to larger options. Retort pouches can include other design considerations such as having tooling available to create a dispenser tip, 55-gallon drum liners with integrated round bottoms, stand up pouches, and other custom shapes and fitments.

Standard Sizes, Custom Sizes, and Printing Available

IMPAK can create customer-specified retort pouch designs using our specially-engineered raw materials. We can produce retortable pouches from 1” x 3” to 30” x 68” and more, in styles that include stand up pouches, drum liners, spouted pouches, and unique shapes. Full custom printing is also available. Call now for more information about your product requirements.

Order Retort Pouches

| Dimensions (w x h) |

Photo | Part Number | Description | Color | Thickness | Material | Order |

|---|---|---|---|---|---|---|---|

| 2" x 5.5" O.D. |

|

DTP02PCA055 | Dispenser Tip Pouch Die-Cut Material: PAKVF4PCA Thickness: 4.0 mil Tear Notch 5,000 bags/case |

Silver |

4.0 mils | PAKVF4PCA | 1 case: $445.50/ea |

| 2.375" x 3.375" O.D. |  |

02375PCA03375RCTN | 3-Side Seal Pouch Tear Notch on Closed End Material: PAKVF4PCA Thickness: 4.0 mil Rounded Corners 2,000 bags/case |

Silver |

4.0 mils | PAKVF4PCA | 100 - 400 bags: $0.259/bag 500 - 900 bags: $0.189/bag 1,000 - 1,900 bags: $0.159/bag 1 case: $316.00 3+ cases: $182.00/case |

| 4.5" x 6.0" O.D. |

|

045PCA54M06RCTN | 3-Side Seal Pouch Tear Notch 1" from Closed End Material: PAKVF54PCA Rounded Corners 1,000 bags/case |

Silver | -- | PAKVF54PCA |

1 case: $399.70 2+ cases: $379.40/case 5+ cases: $344.20/case |

| 5.75" x 5.75" O.D. |  |

0575PCA54MG0575TNUP | Flat Pouch Unprinted 3-Side Seal Tear Notch 1,000/case |

Gold | 5.4 mils | PAKVF54PCA | 1 Case : $173.65/case 2 - 4 Cases: $157.75/case 5 - 10 Cases : $144.65/case 11 - 19 Cases : $132.55/case 20+ Cases : $102.45/case |

| 5.75" x 5.75" O.D. |  |

0575PCA54MG0575TNP | Flat Pouch Printed 3-Side Seal Tear Notch 1,000/case |

Gold | 5.4 mils | PAKVF54PCA | 1 Case : $173.65/case 2 - 4 Cases: $157.75/case 5 - 10 Cases : $144.65/case 11 - 19 Cases : $132.55/case 20+ Cases : $102.45/case |

| 5.75" x 7.875" O.D. |  |

0575PCA45MG07875TNRC | Flat Pouch with Rounded Corners PMS 10121c 3-Side Seal Tear Notch 1,000/case |

Gold - PMS 10121C |

PAKVF45PCA | 1 Case : $179.60/case 2 - 4 Cases: $165.90/case 5 - 10 Cases : $153.45/case 11 - 19 Cases : $137.10/case 20+ Cases : $105.85/case |

|

| 5.75" x 8.0" O.D. |  |

0575PCA54MG08TN | Flat Pouch Unprinted 3-Side Seal Tear Notch 1,000/case |

Gold | 5.4 mils | PAKVF54PCA | 1 Case : $185.75/case 2 - 4 Cases: $170.40/case 5 - 10 Cases : $156.75/case 11 - 19 Cases : $142.60/case 20+ Cases : $108.50/case |

| 5.75" x 8.0" O.D. |  |

0575PCA54MG08TNP | Flat Pouch Printed 3-Side Seal Tear Notch 1,000/case |

Gold | 5.4 mils | PAKVF54PCA | 1 Case : $185.75/case 2 - 4 Cases: $170.40/case 5 - 10 Cases : $156.75/case 11 - 19 Cases : $142.60/case 20+ Cases : $108.50/case |

| 6.5" x 10.0" x 3.5" O.D. |  |

065PCA10BG035 | Stand Up Pouch Two Tear Notches Unprinted Designated for Hot Fill, Retort, Autoclavable 1,000/case Q1 increased production = REDUCED PRICING! |

Silver | 4.0 mils | PAKVF4PCA | 1 Case: $325.91/case 2-4 Cases: $303.66/case 5+ Cases: $283.33/case |

| 6.68" x 7.5" x 3.0" O.D. |  |

0668PCA075BG03TN2 | Stand Up Pouch Two Tear Notches Unprinted Designated for Hot Fill, Retort and Autoclavable 1,000/case |

Silver | 4.0 mils | PAKVF4PCA | 1 Case : $415.60/case 2 - 4 Cases : $380.65/case 5+ Cases : $346.45/case |

| 14" x 18" O.D. |  |

14RCPP18ZTE | Tamper Evident ZipSeal Bag Tear Notch Unprinted Designated for Hot Fill, Retort and Autoclavable 250/case |

Silver | 4.1 mils | PAKVF4RCPP | 1 Case : $756.25/case 2 - 4 Cases : $679.95/case 5 - 9 Cases : $453.75/case 10 - 19 Cases : $416.00/case 20+ Cases : $397.65/case |

| 8.5" x 11" x 4" O.D. |  |

SP64OZPCATRC | SpoutPAK™ Stand Up Pouch Fill Through Spout Rounded Corners 15mm Cap With Handle 64 fl. oz. (1,893 ml, 0.5 gal) Suitable for Retort 250 bags/case |

Clear | - | PAKVF4PCAT | 1 Case: $274.15/case 2-4 Cases: $241.05/case 5+ Cases: $175.60/case |

| 10.5" x 13.0" O.D. |  |

105PCA54M13RCTN | 3-Side Seal Pouch Tear Notch 1" from Closed End Material: PAKVF54PCA Rounded Corners 1,000 bags/case |

Silver | -- | PAKVF54PCA | 1 case: $699.70 2+ cases: $679.90 /case 5+ cases: $649.20/case |

| 12" x 13" x 6" O.D. |  |

SP128OZPCATRC | SpoutPAK™ Stand Up Pouch Fill Through Top Rounded Corners 15mm Cap With Handle 128 fl. oz. (3,785 ml, 1.0 gal) Suitable for Retort 250 bags/case |

Clear | - | PAKVF4PCAT | 1 Case: $368.95/case 2-4 Cases: $351.35/case 5+ Cases: $329.05/case |

| 19.25" x 24.5" x 11" O.D. |  |

DLPCA1925H245D11 | MylarFoil Drum Liner Rounded Flat Bottom Suitable for Hot Fill, Retort and Autoclavable 10/case |

Silver | 4.0 mils | PAKVF4PCA | 1 Case : $75.55/case 2 - 4 Cases : $63.20/case 5 - 9 Cases : $57.65/case 10+ Cases : $50.45/case |

| 35.875" x 45" x 22.75" O.D. |  |

RBPCAD2275H45 | MylarFoil Drum Liner Rounded Flat Bottom Suitable for Hot Fill, Retort and Autoclavable 10/case |

Silver | 4.0 mils | PAKVF4PCA | 1 Case : $159.05/case 2 - 4 Cases : $154.45/case 5 - 9 Cases : $150.05/case 10+ Cases : $147.00/case |

| 38.75" x 54" x 23.25" O.D. |  |

DLPCAD2325 | MylarFoil Drum Liner Rounded Flat Bottom Suitable for Hot Fill, Retort and Autoclavable 10/case |

Silver | 4.0 mils | PAKVF4PCA | 1 Case : $155.65/case 2+ Cases : $150.15/case 5+ Cases : $146.30/case 20+ Cases : $144.10/case |

RETORT TO THE RESCUE!

How is retorting and asceptic processing different than traditional industrial canning methods?

Retorting differs from traditional canning methods using metal cans or glass jars as it takes considerably less time to heat the contents to temperature. Retort pouches allow more surface area and even distribution of heat, rather than waiting for the contents to heat from the outside walls to the center through a cylinder.

Retorting technology’s goal is to produce ambient-temperature, shelf-stable, high-water activity, low-acid foods with higher quality than traditionally canned contents.

Why Choose Retortable Packaging?

- • Cost Savings – contents do not have to be blanched or pre-cooked prior which reduces manufacturing and processing time and cost as well as reduced energy and water use

- • Material Handling – reduced packaged weight and dimensions eliminates heavy, bulky cans/jars during handling / waste easy to handle, ship, store, use and dispose of. Bulk waste is reduced, making clean up and disposal a fraction of the space and processing taken up by traditional cans, glass jars or semi-rigid thermoformed containers.

- • Convenient – Consumers find pouches easy to handle, store, and dispose of, as well as retort pouches are easy to open versus needing to puncture metal or require additional tools.

- • Safety – heating liquids in cans can produce dangerous pressure, and opening cans leave raw edges that are sharp, whereas retort pouches are easily and safely handled

- • Better branding – and consumer visibility with larger branding and labelling surface area and product placement

- • Quality - Foods cook safely and evenly, and since overcooking or uneven cooking of canned foods can be avoided.

- • Design Options - Retort packaging comes in multiple sizes and configurations shapes, printable surfaces, with various hanging or standing methods. Packages can be flat, oval, truncated, conical or almost anything that can be imagined and designed, whereas canned or bottled foods have obvious limitations. For more information on over 62 standard and special flexible film options.

What can Retort Pouches be used for commercially?

- • Packaged foods

- • Re-packaging foods for shelf-stable long-term storage

- • Fully cooked ready-to-eat meals (MRE’s)

- • Field Rations

- • Camping, boating, hiking or backpacking rations

- • Space program rations

- • Fish products

- • Pet foods or snacks

- • Beverages

- • Condiments

- • Emergency Preparedness - Using flexible packaging for your emergency supplies

Need more information? Call us now! We have a technical representative available on stand-by to answer your questions!

Contact UsIMPAK Makes Millions

IMPAK Corporation has produced tens of millions of bags and pouches over the last 30+ years! If you have had issues with a product that has been a challenge in flexible packaging, such as subjecting the film structure to delamination, we are well-versed in combatting these types of challenges.

- • Stand up Pouch with no zipper and two tear notches

- • Designated for Hot Fill, Retort and Autoclave applications

- • Suitable for food and pet food packaging as well as non-food products

- • Silver dispenser tip pouch with tear notch, Hot Fill and autoclave ready

- • Can be custom printed for a professional, high-end look

- • Suitable for food and pet food packaging as well as non-food products

55 Gallon Retort-Grade Drum Liners

- • Integrated round bottoms

- • Can be custom printed for a professional, high-end look

- • Suitable for: foods, chemicals, pharmaceuticals, adhesives and more

- • IMPAK is a leading innovator in the production of custom shaped bags

- • Food-grade and FDA Approved materials

- • Suitable for: oils, gels, liquids, pharmaceuticals, vitamins, and more

IMPAK Offers Explosion Proof Sealers

We've placed machines with the Canadian Military, Lockheed Martin and More.Interested in Learning More?

IMPAK produces custom printed pouches and packaging with an emphasis on materials with distinctive barrier properties to protect products from the adverse effects of moisture, oxygen, light and more. Learn about our unique custom capabilities.

High barrier bags are used to preserve and protect products. When paired with an oxygen absorber or desiccant, products enjoy even greater shelf-life and stability. However, selecting the appropriate package is not always as straight forward as it seems.

Not every Industrial Vacuum Sealer applies to every application. There are different models and types of Vacuum Sealers available, and each one of those sealers has different features that can affect the way a production line works.