We are experts in custom sealing machinery and known for our ability to solve complex sealing challenges. Our sealing equipment can be built to specs that meet military and medical cerification by US and European approval agencies for explosion-proof safety standards, in addition to adding validation capabilities, vacuum seal capabilities, and more. We design and manufacture custom sealing equipment to meet the unique needs of our customers. These are made to order and can be purchased in horizontal/vertical orientation, and with seal lengths up to 110" and beyond. Each Explosion Proof unit comes with our state of the art Intelligent Sealing System (iS²) and Temperature Controller (+/- 3deg) for accurate and reliable results every time.

– Article 100 of the NEC describing an Explosion-Proof Apparatus

Class I locations are catagorized by a presence of flammable gasses or vapoprs in the vacinity - such as natural gas, gasoline vapors or other chemical accelerants. In these conditions the potential for a spark to cause ignition cannot be ingored.

Class II hazardous locations have a presence of combustable materials suspended in the air. dist and particals can cause poowerful explosions after being exposed to a spark in certain conditions.

Class III locations have areas with easily ignited fibers close enough to equipment to make a spark a fire hazard.

– Engineering Manager, Major Chemical Producer for U.S. DOD

For projects where the environment requires strict safety standards, Sorbent Systems brings our decades of experience in the packaging space to ensure your equipment maintaines safety and efficiency standards. Especially for those working with US or Foreign militaray organizations understanding your equipments capabilities and certifications is an absolute necessity. If your project requires the full UL / CSA certifications prior to installation, we can work with you to coordinate with the certifying agency ahead of shipment.

For customers who do not need a cerification on file, we offer our "Built In Accordance" option. We use our exerience and most current understandings of certification requirements to build your machine to meet those high specifications. For some customers this can save time and the high certification fees. Please note that this option is not certified by any agency and you take on the risks involved. To this end the unit would no longer be labeled as "Explosion-Proof" without final certifications.

– Project Manager, U.S. Military Munitions Ordnance Group

Built in Accordance with: Class 1 | Div 1 | Group A

Built in Accordance with: Class 1 | Div 2 | Group D

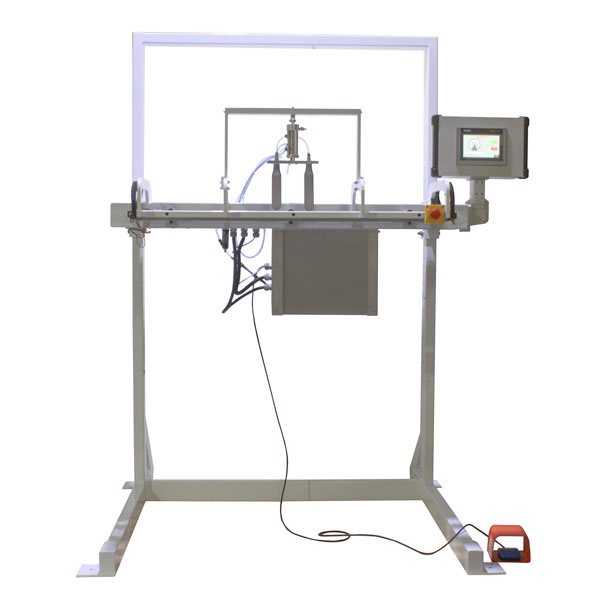

Vertical Vacuum Unit for Military Application

Horizontal Vacuum Unit for Aerospace Application

We mention going up to 110" seal lengths and beyond, but the truth is we make the right machine for your needs. We can provide the same reliability and safety even going smaller to sizes suitable for tabletop.