PARTS

for

RS1575

Sealers

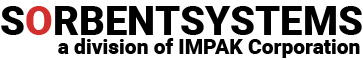

1575 Series - Stainless Steel RapidSealer™ with Dry Ink Printer

Starting Price: $1,376.30

Standard Features:

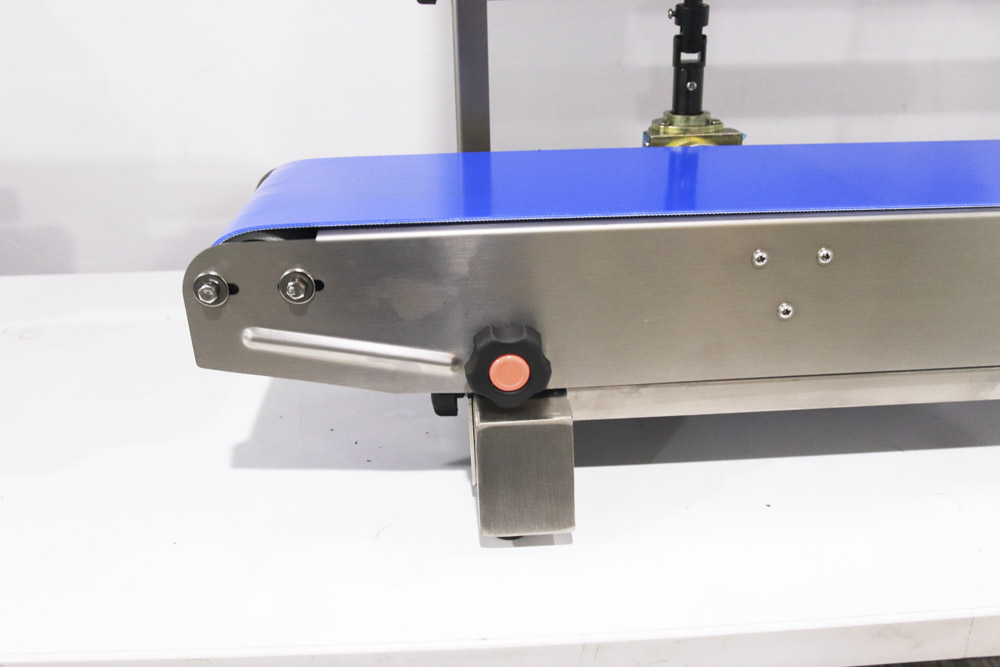

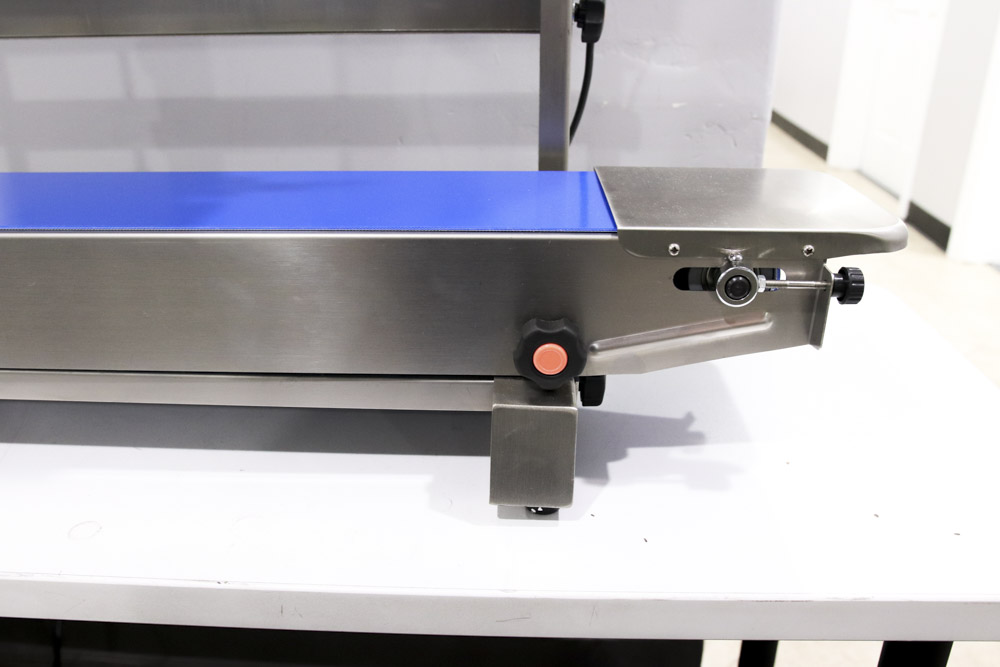

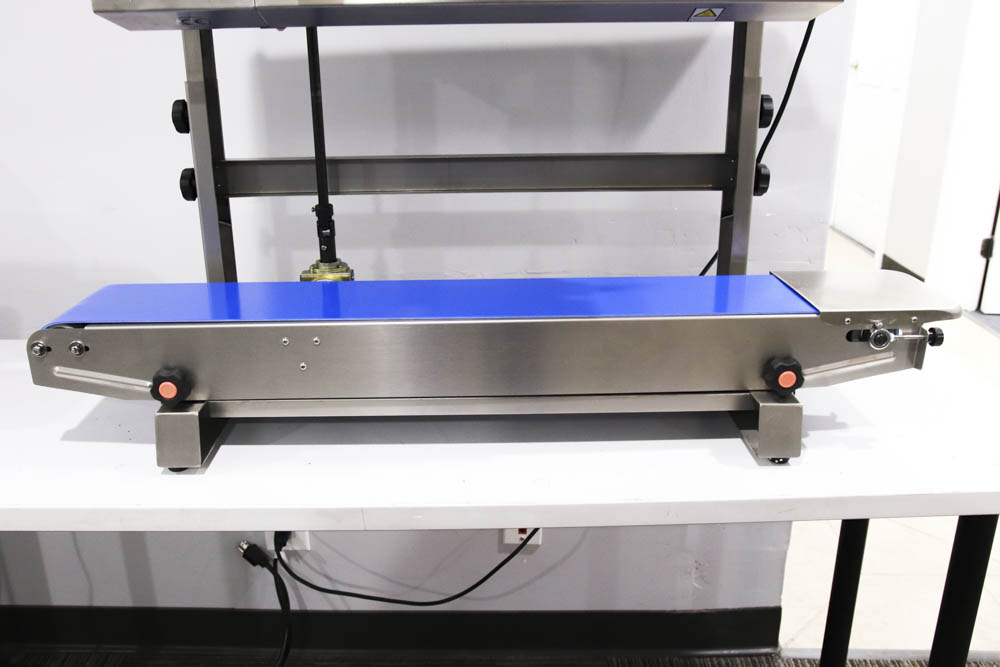

- - All Metal Construction with a Stainless Steel Finish.

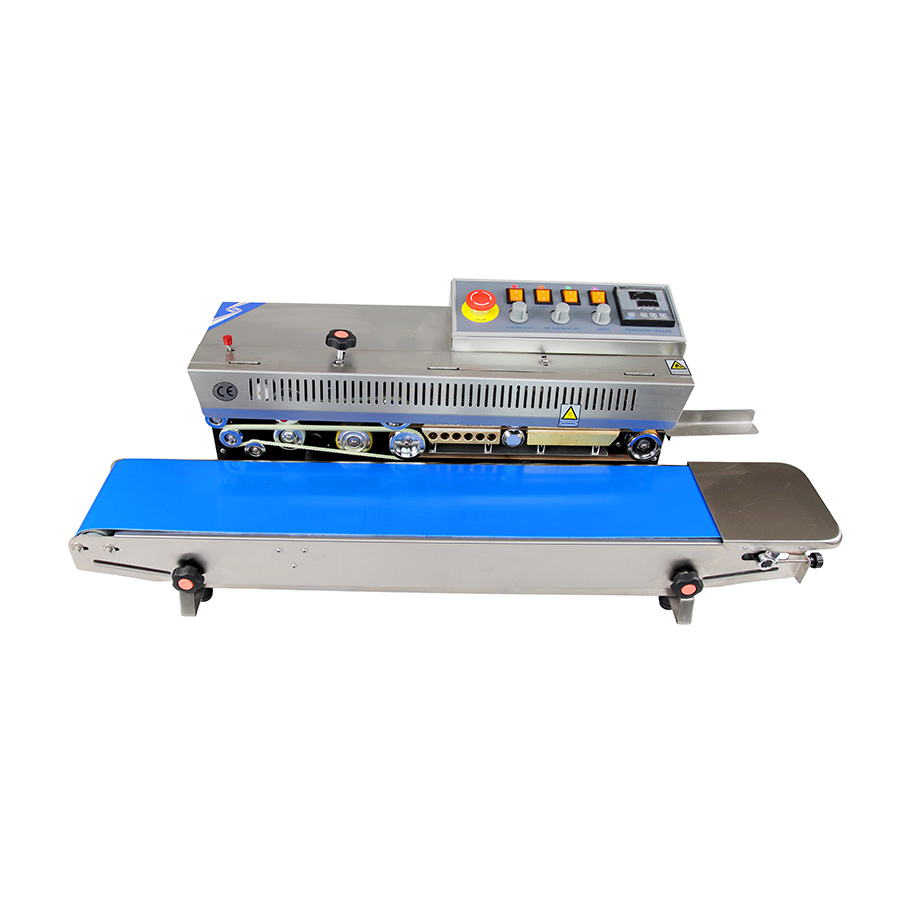

- - Available in horizontal and vertical configurations.

- - Digital Temperature Controller.

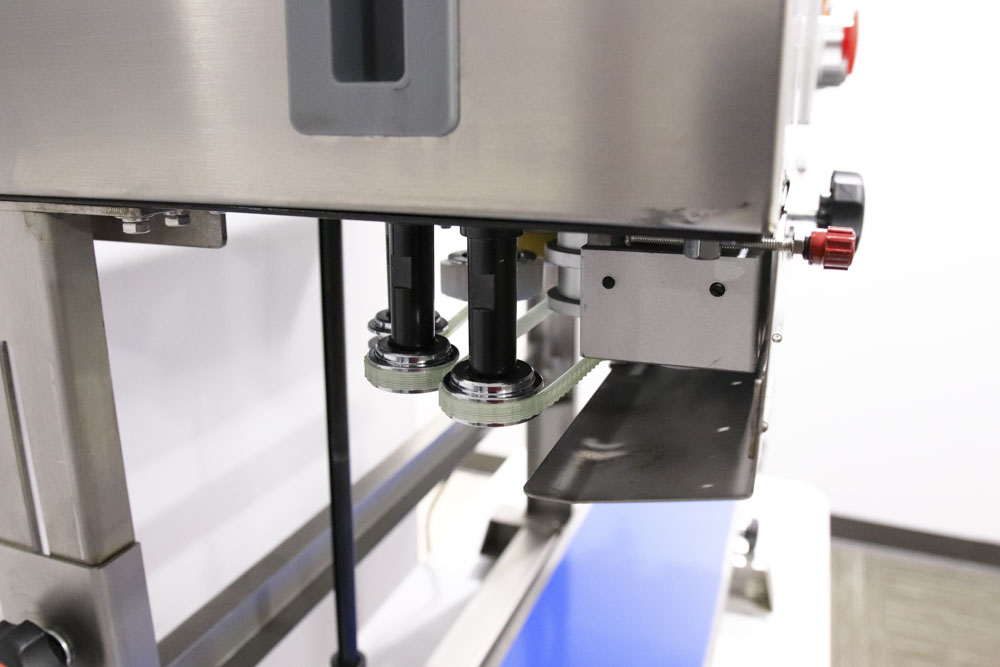

- - Standard Printing Attachment included.

- - Capable of printing up to 20 characters at one time using dry ink pinwheel.

- - Seals a minimum of 45 (Test production: 3.4" x 4" pouches) bags per minute.

- - Warranty: One year parts and labor, not including consumables

- - Various Ink colors include: Red, Black, Blue, White, and Yellow

Horizontal

Stainless Horizontal Steel RapidSealer™ with Dry Ink Printer

Left to Right Feed

Vertical

Stainless Steel Vertical RapidSealer™ with Dry Ink Printer

Right to Left Feed

Stainless Vertical Steel RapidSealer™ with Dry Ink Printer

Left to Right Feed

See our RapidSealer™ with Vacuum Capabilities

See our RapidSealer™ with Gas Flush

See our VakRapid2.5™ system

See our new PrintRapid™ line.

The RapidSealer™ 1575SS Continuous Stainless Steel band sealer is more than capable of sealing a minimum of 45 bags (Example; 3.4" x 4") per minute. It comes equipped with a Dry Ink Printer that allows the customer to print up to 20 characters at one time. Perfect for lot codes, expiration dates and company name, the best part of this feature is that the machine will print on the bag at the same time it seals the bag. Capable of heat sealing at up to 300 C°, this machine is capable of sealing most materials used in flexible packaging. The RS1575SS™ line offers all the needed features for a high production rate at an affordable price.

Horizontal Specifications

| Sealing Speed | 0 - 8m/min (0 - 312"/min) |

| Sealing Width | 6 - 12mm (1/8” - 5/8”) |

| Printing Capabilities | Up to 20 Characters at one time |

| Ink Type | Dry Ink Wheel |

| Temperature Range | 32 - 572° F (0 - 300° C) |

| Voltage | 110V/60Hz (Also available on 220V/50Hz in a wide variety plugs.) |

| Power: | 500 Watts/4.55 Amps |

| Max. Load on Conveyor Table: | 10 lbs. |

| Machine Size: | 38” X 14” X 14” |

| Weight | 99 lbs. / 45 kg. (With Packaging Included) |

Vertical Specifications

| Sealing Speed | 0 - 8m/min (0 - 312"/min) |

| Sealing Width | 6 - 12mm (1/8” - 5/8”) |

| Printing Capabilities | Up to 20 Characters at one time |

| Minimum Bag Height | 7.75" |

| Maximum Bag Height | 13.0" |

| Ink Type | Dry Ink Wheel |

| Temperature Range | 32 - 572° F (0 - 300° C) |

| Voltage | 110V/60Hz (Also available on 220V/50Hz in a wide variety plugs.) |

| Power: | 500 Watts/4.55 Amps |

| Max. Load on Conveyor Table: | 10 lbs. |

| Machine Size: | 38” X 28” X 14” |

| Weight | 99 lbs. / 45 kg. (With Packaging Included) |

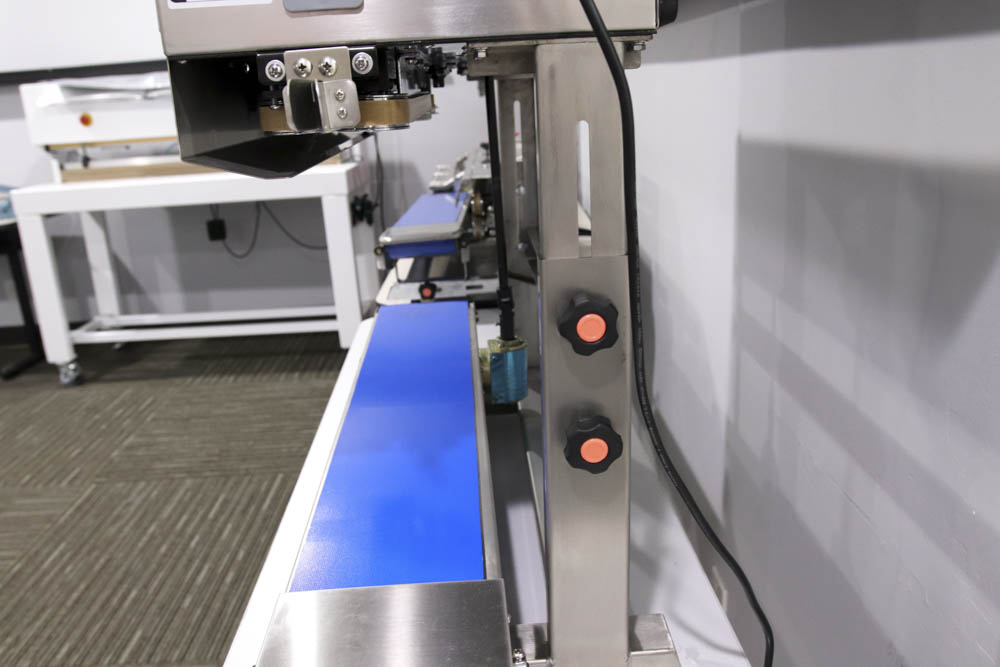

Part Number: 81XSPPRKT

- (2) Urethane Drive Belts

- (4) Clutch Belts

- (1) Main Control

- (1) Temperature Adjusting Printed Circuit Board

- (1) Ink Roller Heating Element

- (1) Sensor

- (1) Brush Kit

- (1) Letter Holder

- (1) Silicon Printing Wheel

- (1) Black Ink Wheel

- (10) 15.75" PTFE Fluoropolymer Bands

$259.95

View Complete List of Spare Parts

Stainless Steel Stand

Part Number: 81XSTNCST

$190.00

Sterile Air

Two Pre-filters with PM indicators which remove contaminants and water from the compressed air line before they reach the nitrogen generator. After leaving the generator the air is pushed through a Post filter which results in a Sterile Nitrogen flow of 99.9999+% efficiency at 0.01 micron. This is essential for food and sensitive applications where purity is critical.

Nitrogen Generator Kit

The Nitrogen generator produces Nitrogen gas (N2) from a standard compressed air line. This model is designed to generate Nitrogen at purities between 95% and 99.5%.

The Nitrogen generator can be used as a replacement for heavy and bulky Nitrogen gas tanks. Its slick and compact design allows users to integrate this with their current gas flush enabled vacuum sealers without having to worry about it taking up too much space. Also, users will not have to worry about a depleting Nitrogen gas source, as our generator produces Nitrogen from a clean compressed air source.

Interested in Learning More?

A hermetic seal on flexible packaging can be achieved with any of our sealing machines, this quick guide will help you choose the unit that will work best for your production needs.

Not every Industrial Vacuum Sealer applies to every application. There are different models and types of Vacuum Sealers available, and each one of those sealers has different features that can affect the way a production line works.

We design and manufacture custom sealing equipment to meet the unique needs of our customers. In addition to new machinery we even retrofit our customers’ existing equipment, regardless of the brand.