Do you have an idea for a fitment or pour spout? At IMPAK, we design and produce flexible packaging with unique fitments that can meet the varied needs of our customers. We are known in the industry for having the ability to take on any project, no matter how big or small and regardless of the complexity. Spouts and fitments offer a new functionality to flexible packaging…..the SpoutPAK™

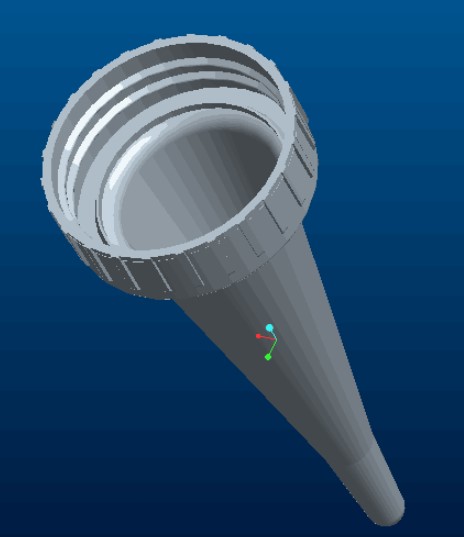

Not to be confused with a person from New York, a Yorker Spout is a cap, or lid, that you would attach to a standard threaded fitment. It is a great option for dispensing chemicals, liquids, oils and many other applications because they help control the direction and volume of the product being dispensed.

Patented in 1964 by Oscar B. Yorker and Jack R. Pechman, the Yorker Spout was created to provide a novel and improved spouted cap closure suited for use on dispensing containers filled with liquid adhesives and foodstuffs. Another object of the invention was the provision of a tapered spout that would be suited for spreading and leveling the dispensed material into a layer of uniform thickness, like cake icing.

The previous pouring spout closures had many problems that included spillage during shipment, failing to provide air-tight seals for the containers, and the closures oftentimes would become glued to the spout to the extent that it was difficult, if not impossible, to remove without damaging the container. Additionally, spouted caps and closures have a threaded connection and the threads would usually become filled with the adhesive or other air-setting material making it virtually impossible to separate them.

Founded in the 1920’s, CSS Inc.* packaged their sealant in a traditional caulking tube since inception. They were looking to modify their product into a foil stand up pouch with a custom Yorker fitment to dispense the sealant.

They began by looking for a Yorker cone-shaped nozzle that would attach to a standard fitment. Even though they found several possibilities, nothing was compatible with their existing flexible pouch.

CSS Inc. contacted several injection molding companies to develop a custom nozzle and received quotes where the minimum order quantity was at least 375,000 pieces. This was quite an investment for a product that had not been tested and approved for their target market as of yet.

After contacting IMPAK with their vision of their future packaging using a moisture barrier foil stand up pouch with a dispenser tip, or spout, IMPAK was able to provide samples of our stock SpoutPAKs for CSS Inc. to evaluate the fitment opening they would like their product to dispense.

CSS Inc. decided to move forward with our stock 33mm fitment that would dispense their product at a greater volume. IMPAK’s engineers developed a custom drawing for a cone shaped dispenser tip (Yorker spout) that would be compatible with our stock oxygen sensitive stand up pouch approved by CSS Inc.

An 8-cavity mold was created to produce the first article for CSS Inc. approval. The customer tested samples and moved forward with an order of 25,000 pieces. This was a significantly lower quantity requirement than quotes they received from other suppliers.

IMPAK worked closely with our injection molding suppliers and we were able to obtain a trial order of 25,000 units successfully. The standard minimum order for a new customer is 250,000 units but due to our relationship with our supplier, we were able to produce only 25,000 units.

Over the years, the volume has increased and now, CSS Inc. is an IMPAK red carpet customer.

CSS Inc. now also purchases IMPAK’s 55-gallon drum liners to line their drums before filling with sealant - saving them thousands of dollars in packaging costs.

They have established a drum buy-back program to reuse them after their customer has used the sealant packaged in the liner.

For more information regarding drum liners visit our Drum Liner page.

For more information regarding custom projects Contact Us.