Case ready meat applications have specific requirements, both in terms of shelf life and in terms of the low-temperature environment in which the oxygen absorber must work, that require a specific formula in order to achieve the appropriate oxygen level in the right time over the life of the package. While the barrier properties of the mother bag are critical to success, the right formula will not only bring down the oxygen level quickly at low temperature, but also continue to absorb oxygen whether it is released from packaging media (foam trays) or the muscle tissue of primal cuts. Such a formula is the fundamental key to success in case ready meat packaging.

"IMPAK realizes that the goal of meat processors was not simply to provide a product with a longer shelf-life but rather a safe, consistent, quality product delivered quickly, utilizing just-in-time inventory controls and tightly controlled cold chain management."

--TS, QA Supervisor - Major Meat Plant

At this time, IMPAK can readily supply two different sized packets from inventory that are designed to work rapidly and efficiently in the meat packaging environment. Custom formulations have been produced for both domestic (USA) and European customers.

Please contact our regional technical representatives for further assistance.

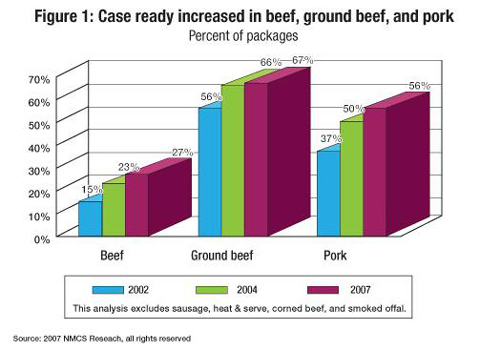

Centrally processed, case-ready (CPCR) meat presents a unique set of challenges and opportunities for both the processor and the retailer. The advantages CPCR offers to retail locations are clear - diminished labor costs, reduced meat losses, and added flexibility.

The move to CPCR presents benefits across the meat packaging system. With Modified Atmosphere Packaging (MAP), the shelf life of case ready meat is significantly enhanced, while eliminating labor costs and ensuring a presentable package. CPCR has long been the industry norm in Europe, where IMPAK's specifically developed StayFresh Products have been accepted and used. Currently, the economically efficient, case-ready system is rapidly taking hold across the United States.

Color stability can be the most challenging issue in CPCR success - its control is paramount because color is essential to a package's marketability.

Why is the elimination of oxygen so critical for color stability? Oxygen turns meat bright red because the meat's myoglobin requires oxygen. Deprived of oxygen, for example during vacuum packaging, carcass meat has a purple color, and after having been overexposed to oxygen, it turns brown. Although this is a natural change, and although the product remains fresh and edible, this process can be rather unappealing to consumers.

The idea behind case ready meat is that it is made ready to take oxygen at just the right time - shortly after arrival at supermarket locations. After being removed from the mother bag and exposed to oxygen, meat turns bright red once again. Such color change is referred to as "blooming." Blooming occurs so quickly that it is difficult to capture the purple color of oxygen-deprived meat with a camera.

To prevent browning, low-oxygen MAP packages should lower the oxygen levels to Parts-Per-Billion (in a tested and proven period of time) from the package. Moreover, the addition of small amounts of carbon monoxide can help ensure that the red color remains even after the meat product is saturated with oxygen.

Both high and low oxygen systems are in use to package meat in the case-ready format. What is the difference between the two systems? In high oxygen MAP, 60-80% of the gas is O2 and the remainder is CO2. In low-oxygen MAP, the oxygen is reduced to significantly less than 1% and replaced with carbon dioxide and nitrogen.

High-oxygen MAP occurs when the meat is kept in a bright red state for a relatively shorter period of time. The high oxygen approach is limited to a regional level of distribution because the shelf life is 7-10 days, and distribution time takes away from the display life. After that period of time, the meat can easily become rancid. In the case of beef, the regional packer uses wholesale cuts that are vacuum packaged and aged at the time of processing. Such limitations reduced the potential for high oxygen MAP packaging.

A different approach to MAP that has produced exceptional results is to create a low-oxygen environment within the package. Oxygen, which gives meat its red color, also encourages the growth of bacteria on meat and can be harmful for the shelf life of stored food. Meat is particularly susceptible to bacterial growth due to their high water activity (AW) and nutrient content. Such bacteria affect the color, taste, and shelf life of the meat. Moreover, the removal of oxygen from the MAP package allows the meat to bloom after it is placed on store shelves.

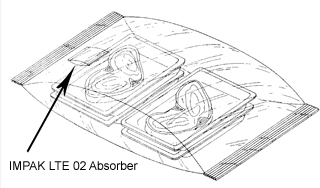

CPCR meats can be successfully packaged using modified atmosphere packages containing IMPAK's StayFresh CR or FA system. These packages consist of small, individually wrapped trays, which are permeable to oxygen, and a large, impermeable mother bag. The mother bag is a high barrier bag into which individual pre-wrapped trays of meat are packed. The bag is vacuumed and then gas flushed prior to sealing. In gas flushing, the air within the mother bag is changed to a desired composition. O2 is replaced with carbon dioxide (CO2), which can lower the pH and inhibit the growth of bacteria, and N2, an inert gas, neither encouraging nor discouraging bacterial growth.

The mixture also includes a minuscule amount of carbon monoxide (CO) - up to 0.4% CO has been approved by the FDA and categorized as GRAS* as recently as 2005 - to help the meat retain its red color and prolong the shelf life of the product. Additionally, an oxygen absorber packet - critical to the success of the MAP system - is placed into the master bag, which absorbs any residual oxygen from the meat packets.

Do you want to provide your customer with the "in-store" processed look? Even when modified atmosphere packages are flushed with carbon dioxide and nitrogen, a small amount of residual oxygen present within the meat can and will decrease the shelf-life of the product, even leading to spoilage. Low-oxygen case ready meat packing can be enhanced by the use of oxygen "scavengers" or "sorbents" to absorb any residual oxygen left after the bag is flushed with gas. Oxygen scavengers tend to remain hidden from consumers, usually in the mother bag. These oxygen absorbers help extend the shelf life of the package to 21-28 days.

At the retail store, the mother bag is opened and the trays placed into the counter. The trayed product *Generally Recognized As Safe, keeps the traditional fresh processed look and appeal. Traditional counter life is maintained after the mother bag is opened. A new two compartment mother bag allows the retailer to open only one side for counter use, the other compartment stays under vacuum/gas for a later time, allowing meat to remain packaged until the time it is most needed.

IMPAK recognized that the goal of meat processors was not simply to provide a product with a longer shelf-life but rather a safe, consistent, quality product delivered quickly, utilizing just-in-time inventory controls and tightly controlled cold chain management. Utilizing its experience in the industry, IMPAK has designed and created a series of oxygen absorbers specifically for the environmental factors related to case ready meat production and the demands of high volume production and rapid reduction in residual oxygen levels. The packets utilize a gas permeable material whose structure is designed to provide rapid reduction and then renew its efforts as entrained oxygen either under the meat tray or from the muscle must be absorbed in the crucial initial 48 to 72 hours. In a recent test, IMPAK oxygen absorber packets performed equivalent if not superior to Product AX oxygen absorbers within the MAP master bags, proving that IMPAK oxygen absorbers effectively remove residual oxygen from CPCR products.

It's a fallacy to believe that the purpose of CPCR meat is simply to lower costs and extend distribution because we know that the primary purpose is to provide a safe, consistent, quality product delivered quickly, using just-in-time inventory controls and tightly controlled cold chain management.

As interest in CPCR meat grows, IMPAK will be there to meet the needs of a growing and changing industry.

All IMPAK products are compliant with applicable sections of Title 21 Code of Federal Regulations (CFR) standards for food contact materials. These standards are followed even though there is no food contact in the master bag.