Starting Price: $9,180.00

Available Seal Lengths: 21.0", 26.0", 31.0", 36", 41", 51", 61"

Standard Features:

Due to the size and weight of these machines they will require crating and freight. Final weight and dimensions are only taken after crating is complete. For cases like these we do not charge shipping for those items through the site, but will follow up with an accurate calculation at a later date.

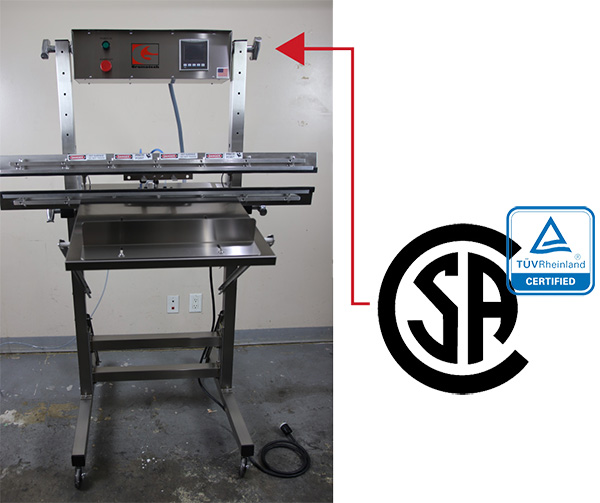

IMPAK is proud to partner with a major Multi-National Pharmaceutical Company and to have been granted a CSA Certification for its industry leading line of Gramatech Vacuum Heat Sealers. “We are now ready to offer CSA registration as an option to our industry leading line of Gramatech Sealers,” according to Rajib Hasan, Managing Director, Machine Group.

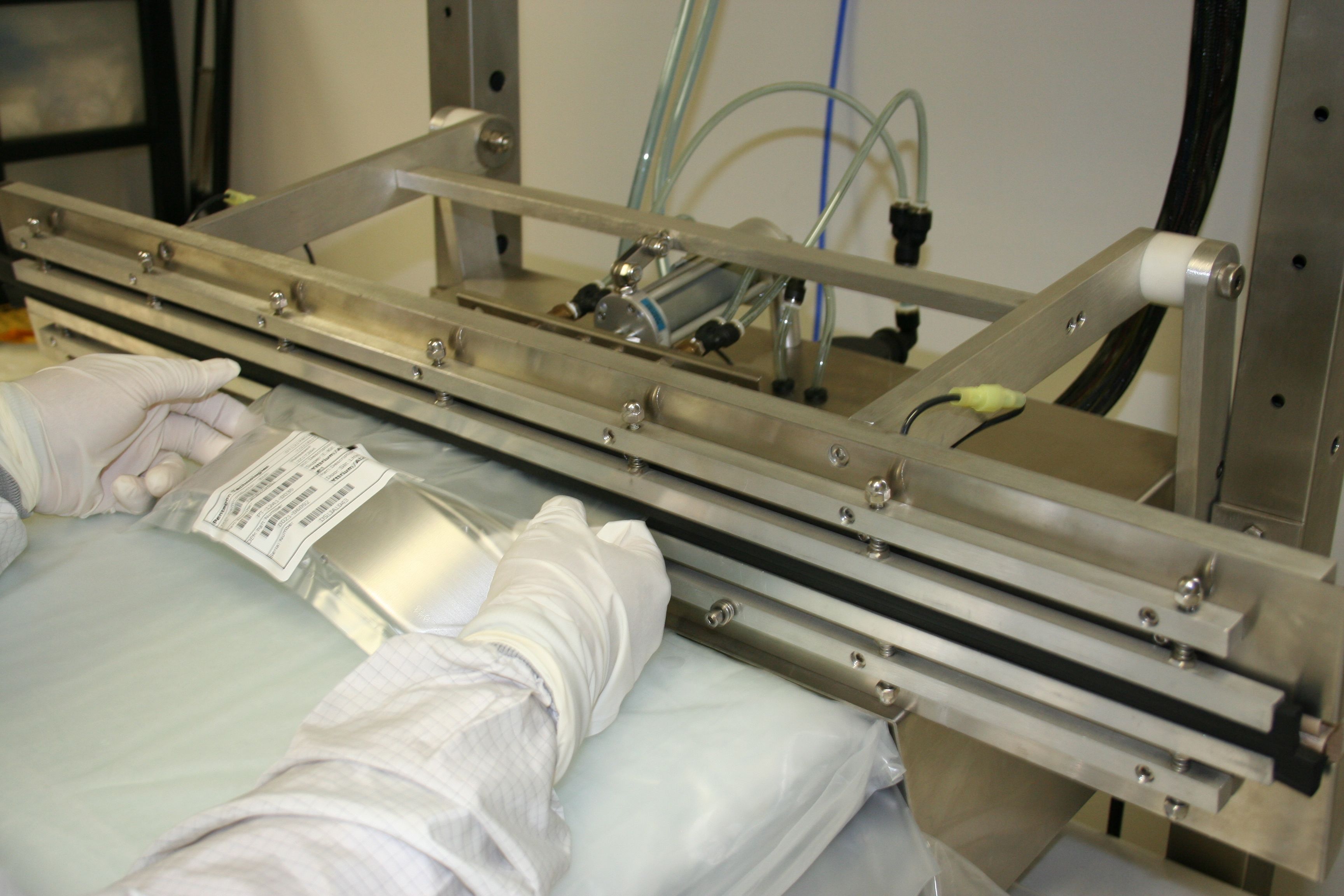

As the company General Manager has said, “We are very proud of the machinery we have built to CSA standards.” The story below written by Alan Masnek, our resident Certified Packaging Professional (CPPL) and graduate of University of Wisconsin – Stout, illustrates the steps that were taken to design, develop and produce a piece of equipment for pharma MNC. This particular MNC is just one of the many top medical manufacturing firms we are proud to have produced product for... [see full article]

This vacuum sealer machine with mobile stand and separate control head is made from high-grade stainless steel and quality anodized aluminum frame body. This retractable vacuum sealer comes with dual heat elements, PLC touch screen, single-ported exhaust, stainless steel frame, Venturi vacuum pump, and double retractable nozzles as standard features.

Features

Review a PDF copy of our Modified Gramatech Custompak

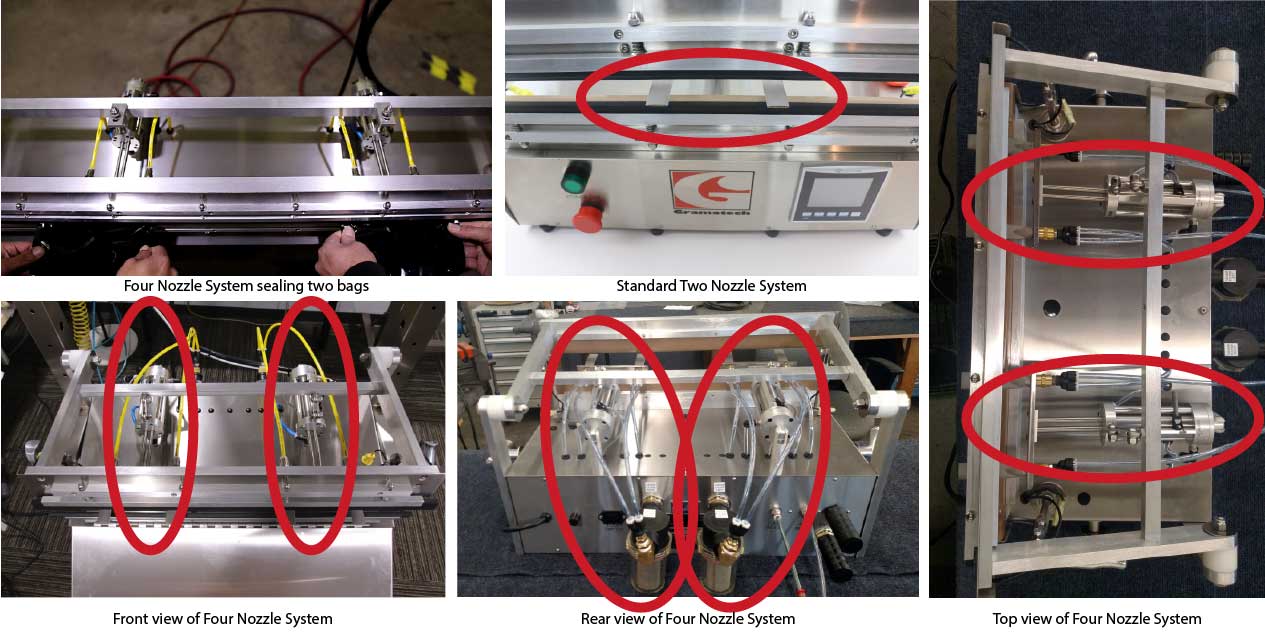

Our technicians who build these heat sealers state that the Trident option provides the most value of any option on Gramatech machines.

For more information, see the options tab.

Medically Validatable 36 Inch Workhorse with Optional Trident System

IMPAK is the Global Approved Manufacturer of vacuum sealing equipment to Pentagon Technologies, an Applied Materials partner

| Sealing Lengths | 21", 26", 31", 36", 41", 51", 61" |

| Seal Width | 0.25" Standard |

| Vacuum Pressure | 25 hg |

| Vacuum Flow | 17 scfm |

| Air Consumption | 7 cfm |

| Electrical | 120 VAC, 15 amps |

Part Number: GK-GV21

Price: $218.00

Part Number: GK-GV26

Price: $225.70

Part Number: GK-GV31

Price: $237.10

Part Number: GK-GV36

Price: $253.00

Part Number: GK-GV41

Price: $575.400

Part Number: GK-GV51

Price: $798.100

Part Number: GK-GV61

Price: $907.700

51" Custom Pak with Trident Nozzle System

51" Custom Pak - Bag Spreader Option

Custom Pak Vacuum Sealer

Medically Validatable 36 Inch Workhorse with Optional Trident System

GVS Auto Cycle - Option Feature Demo

Purge Flush Option - Gramatech WorkHorse Unit

High Flow Vacuum Sealer (Medically Validatable)

Medically Validatable 36" Custom Pak with Vacuum and Gas Flush

IMPAK produces custom printed pouches and packaging with an emphasis on materials with distinctive barrier properties to protect products from the adverse effects of moisture, oxygen, light and more. Learn about our unique custom capabilities.

High barrier bags are used to preserve and protect products. When paired with an oxygen absorber or desiccant, products enjoy even greater shelf-life and stability. However, selecting the appropriate package is not always as straight forward as it seems.

Not every Industrial Vacuum Sealer applies to every application. There are different models and types of Vacuum Sealers available, and each one of those sealers has different features that can affect the way a production line works.