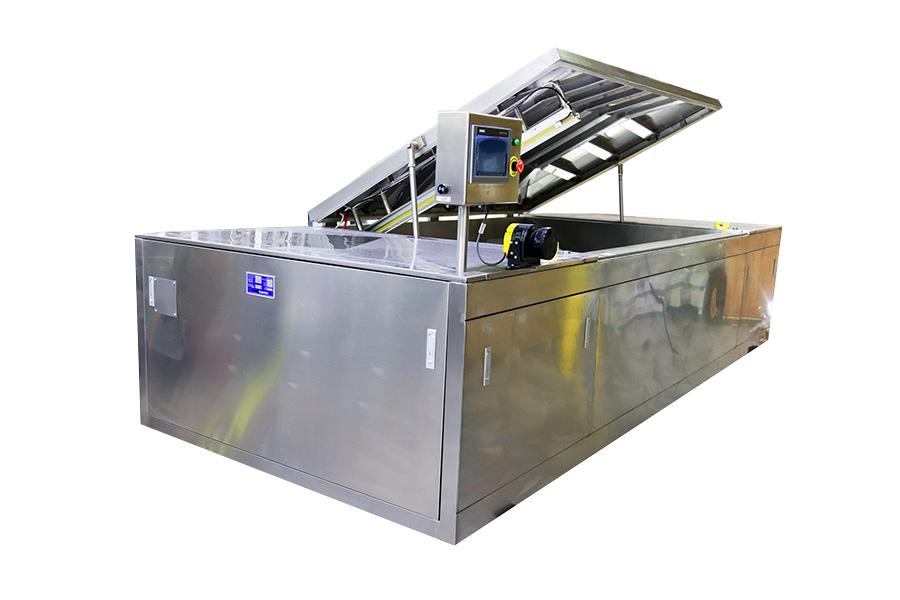

There are applications that require a vacuum chamber sealer to be designed specifically to meet the needs of that application and that is where a Gramatech custom chamber unit in. Gramatech custom chamber units can be either a stock model modified with several standard options or a machine designed from the ground up to meet the specific needs of your application.

The in-house engineering team at IMPAK has designed chamber vacuum sealer units that require very large vacuum cavity areas for extra large products as well as a vacuum system that can delivery a very high vacuum pressure in a very short time. The team has also delivered ergonomic options that help prevent repetitive motion injuries such as an auto lid system on a table-top unit. Custom PLC/HMI programming is also available across a wide selection of hardware so if your company has standardized on a specific PLC brand IMPAK can offer a complete control system solution within that brand otherwise our standard Siemens based PLC/HMI controls systems offer state of the art hardware choices.

The bottom line is IMPAK can built a custom vacuum chamber sealer that will meet all the needs of your specific application. Contact a vacuum chamber sealer specialist at IMPAK today to discuss your application.

If you are preparing for the possibility of a food shortage or disaster, IMPAK supplies the necessary materials for long-term food and product storage.

A hermetic seal on flexible packaging can be achieved with any of our sealing machines, this quick guide will help you choose the unit that will work best for your production needs.

Not every Industrial Vacuum Sealer applies to every application. There are different models and types of Vacuum Sealers available, and each one of those sealers has different features that can affect the way a production line works.